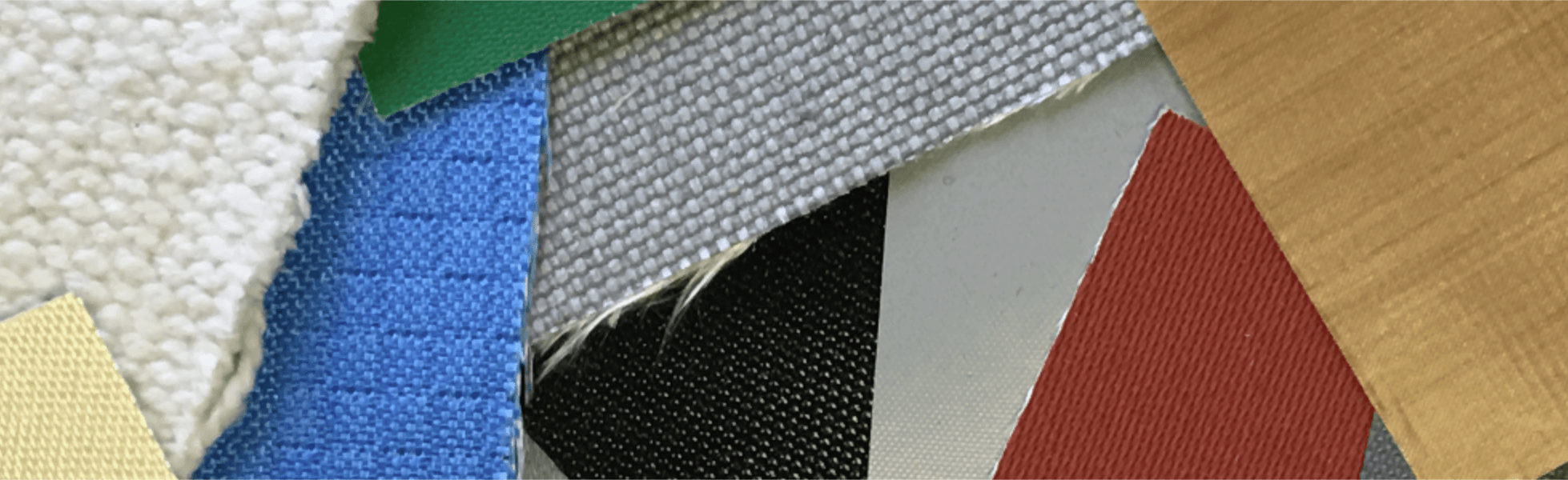

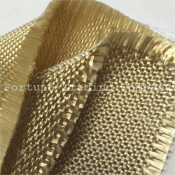

Heat Treated Fiberglass Fabrics

Heat treated (caramelized) fiberglass fabrics are passed through an oven at a high temperature. The high heat burns the organic elements in the fabrics. This makes the heat treated fiberglass fabrics smoke-free during application.

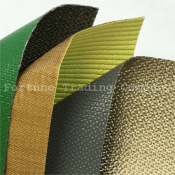

Acrylic Resin Coated Fiberglass Fabrics

Acrylic Resin (Neoprene) coated fiberglass Fabrics is a material that is flame retardant and resistant to aging, corrosion, and oil. After the coating treatment, it has a strong resistance to flame and great resistance to water, as well as having high chemical stability. This makes it especially useful in the elastomeric industry.

Vermiculite Coated Fiberglass Fabrics

Vermiculite coated fiberglass fabrics are made of fiberglass coated with vermiculite which provides a natural inorganic finish. This special coating gives it a continuous temperature resistance of up to 750C/1382F and a short term temperature resistance temperature of up to 1000C/1832F. Vermiculite coated fiberglass fabrics also has an increased resistance to abrasion, which allows it the ability to withstand direct flame, as well as dust suppression.

PTFE Coated Fiberglass Fabrics

PTFE fiberglass membranes can be installed in climates ranging from the frigid arctic to the scorching desert heat with an expected project life exceeding 30 years.

Aluminum Laminated Fiberglass Fabrics

Fiberglass fabrics laminated with aluminum foil increase the resistance to heat radiation. Aluminum laminated fiberglass fabrics is a great material for daily apparatus protection, safety defender for manufacturers, storage, and transportation of dangerous material. It is also a good protection for outside piping systems.

Ceramic Fiberglass Fabrics

Ceramic fiberglass fibers is a lightweight, a low thermal conductor and has a strong chemical stability protecting it from most corrosive agents. This cloth is widely used in welding, foundry works, aluminum and steel mills, boiler and seal insulation, shipyards, refineries, power plants and chemical plants.